Investment Casting

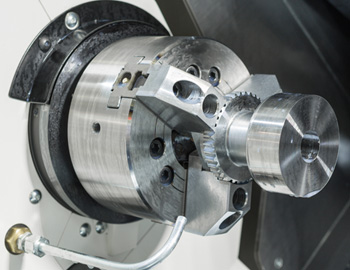

Welcome to Sulcon Technocast Industries! We are passionate about creating high-quality precision machined components through Investment Casting, Sand Casting, and Forging processes. Our expertise spans a variety of metals and high-performance alloys, including Stainless Steel.

Our journey began over a decade ago with a commitment to producing and exporting reliable auto parts. Since then, Sulcon Technocast Industries has grown steadily by adhering to our core values: crafting precision investment casting components and auto parts that our customers can trust.

At Sulcon Technocast, we seamlessly blend modern performance technologies with traditional investment casting techniques. This ensures our products not only meet but exceed your expectations. We are globally recognized for our products' fine finishing, high accuracy, and impeccable designs. Every piece we create reflects our dedication to excellence.

With a diverse range of casting solutions and a strong focus on quality, we have become a preferred partner for OEMs and companies around the world. At Sulcon Technocast Industries, we are committed to providing you with the best in casting, backed by a team that genuinely cares about your success.