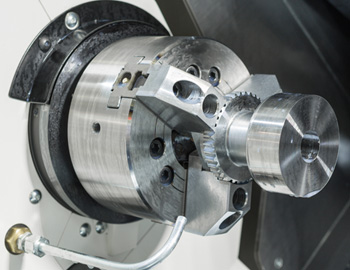

Precision Machined

At Sulcon Technocast Industries, we're proud to be a leader in the world of CNC Precision Machined Components. Whether you need short-term or long-term production runs, prototypes, or new designs, we’ve got you covered. We specialize in complex and precision parts and assemblies with tight tolerances.

Our in-house precision machining capabilities are state-of-the-art. We have a full range of highly precise CNC machines, including VMC and HMC, with everything from 7-axis machining down to 2-axis with rotary tables and twin pallets. This allows us to handle multifaceted machining jobs with ease. Our sophisticated in-house equipment includes centerless, cylindrical, and flat surface grinding, internal bore grinding and lapping, broaching, slotting, spherical milling, vertical milling, thread milling, and CNC wire cut EDM machines with high-speed EDM drilling. All of this ensures we can meet your demands for tight and highly precise tolerances.

Our CNC turning centers can handle machining up to 350mm in diameter. Our CNC vertical machining centers are capable of handling prismatic components up to 800mm by 500mm. Additionally, our horizontal machining centers are equipped with 4-axis rotary tables for multi-axis machining in a single setup. We even have a twin pallet horizontal machining center that can handle a variety of complex machining jobs.

At Sulcon Technocast Industries, precision is not just a goal—it’s a promise. Our advanced technology and skilled team ensure that every component we produce meets the highest standards of quality and accuracy.